- Completely made out of stainless steel

- Inner tray sound and heat isolated

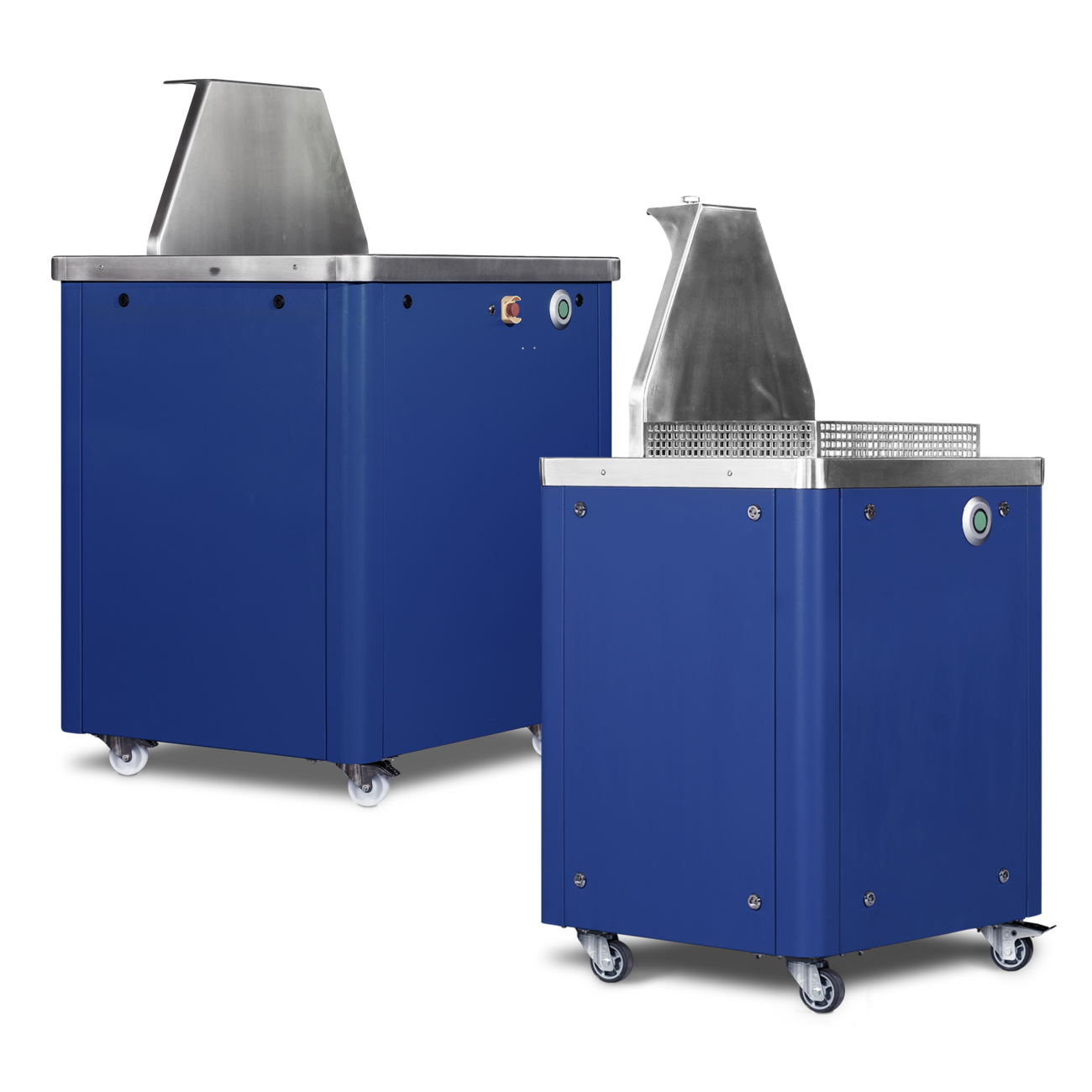

- Mobile device on rolls

- Fully programmable lifting/lowering function (speed-dwell time, etc.)

- Cleaning time digitally adjustable

- Control via Mini - Touchdisplay

- Integrated heating; heating up to 80 degrees possible

- Temperature Management

- Preparation for external filtration

- Ground sound: Ultrasonic transducers are fixed on bottom side

- Side sound: Ultrasonic transducer available on both sides

- Ultrasonic frequencies from 25 kHz to 132 kHz

- Ultrasonic transducers are manufactured according to customer specifications

- Generator power from 300 W to 3000 W

- Power control from 10 & - 100 % in 1% steps

- Frequency monitoring

The rinsing and preserving basin is entirely made out of stainless steel. Due to its atable design and high quality components, it is specifically constructed for industrial use. The system is controlled y a programmable system control. The rinsing and preserving basin is a closed unit with an entegrated control cabinet.

Cleaningstation V10 - S

|

Dimensions

|

|

| Width | 780 mm |

| Loading - Height | 910 mm |

| Depth | 755 mm |

| Inserted Basket | 600 mm x 400 mm |

| Additional details | |

| Drip tray | Corrision-resistant stainless steel |

| Control | Mini - Touchdisplaycontrol |

Cleaningstation V10 - L

|

Dimensions

|

|

| Width | 1000 mm |

| Loading - Height | 1.100 mm |

| Depth | 850 mm |

| Inserted Basket | 700 mm x 525 mm |

| Additional details | |

| Drip tray | Corrision-resistant stainless steel |

| Control | Mini - Touchdisplaycontrol |

Potential processes:

- Washing

- Rinsing

- Preserving

Additional options:

- Tray heating with temperature control

- Ultrasonic cleaning

customer-specific production is always possible.